In this comprehensive guide to all things adhesive tape, we’re sharing 45 years of experience with you. Read on to find out why adhesive tape is quickly replacing glues and fasteners in manufacturing and construction, and how you can use it on your project today.

What is Adhesive Tape?

Adhesive tape (a.k.a. pressure sensitive tape, PSA tape, self-stick tape, or sticky tape) consists of a pressure-sensitive adhesive coated onto a backing material such as paper, plastic film, cloth, or metal foil.

Some tapes have removable release liners that protect the adhesive until the liner is removed. Some have layers of adhesives, primers, easy release materials, filaments, printing, etc. made for specific functions.

Pressure-sensitive adhesives (PSAs) do not require water, solvent, or heat activation to bond to materials such as paper, plastic, glass, wood, cement, and metal.

PSA tapes are tacky at room temperature in dry form, and they adhere firmly to a variety of surfaces and require only the application of a finger or hand. Technically speaking, that’s a bonding pressure of 14.5 – 29 psi =^ 10 – 20 N/cm² or greater.

Single-sided tapes allow bonding to a surface or joining of two adjacent or overlapping materials. Double-sided tape (adhesive on both sides) allows the joining of two items back-to-back.

A Brief History of Tape

The history of stickiness didn’t start with tape. It’s credited to the bees. Or rather, woodworkers in ancient Egypt used glue made from natural, viscous substances like beeswax and resin to hold materials together.

In modern times before tape, glues and epoxies did most of the sticky work. But they had serious drawbacks, especially in household use. Messiness, permanence, and drying to a hard finish all made traditional glues less-than-ideal.

It wasn’t until 1925 that adhesive tape, as we know it today, was invented.

According to How Stuff Works:

« Masking tape, as it became known, was intended to solve a very specific problem: applying two-toned paint jobs to cars. Before masking tape, auto shops were “masking off” for each color application using glue and paper. Peeling off the paper ruined countless paint jobs. Richard Drew, a young research assistant, witnessed one such ruined job and the furious cursing that followed. Drew, who had absolutely zero experience in adhesives, decided, apparently on the spot, to create an adhesive that could be removed from dry paint without peeling it off. Two years later, masking tape was introduced. »

Today, adhesive tape comes in all shapes and sizes, with varying degrees of stickiness, and for close to 45 years, ECHOtape has helped our customers match their specific application needs with the right pressure-sensitive tape.

And in that time, we have found that the majority of people have the same complaints and questions about tape. Here’s almost everything you need to know about adhesive tape as an industry professional.

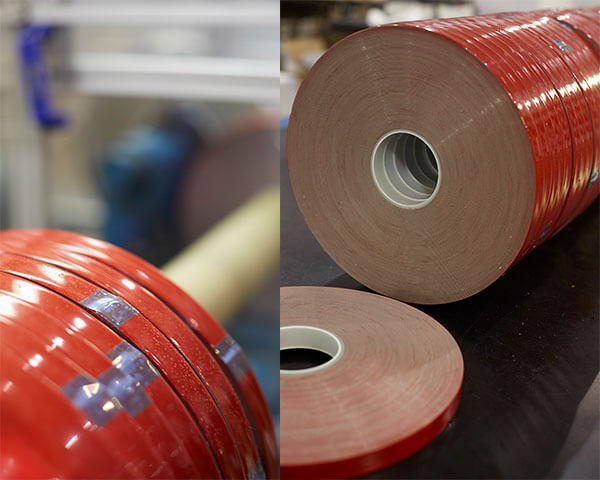

How is Adhesive Tape Made?

We could tell you how adhesive tape is made, but this video by The Science Channel is much more fun:

https://www.youtube.com/watch?v=Y3N-MfmSAPg

As an aside, this video is also a great example of how tape is used in splicing. But that’s another topic for another time.

What Makes Tape Stick?

While the adhesive used on pressure-sensitive tapes might seem alike – they are all tacky, adhere well, and resist stresses – they are actually quite different. There are pros and cons for each tape type, be it rubber/resin, synthetic rubber, acrylic, and silicone-based adhesives.

Rubber/Resin is the oldest type of adhesive based on natural rubber, but it needs a resin to make it into an adhesive.

For many jobs, rubber/resin adhesives offer many advantages:

- It is often a less expensive adhesive.

- Has an initial high tack, as opposed to acrylic which needs time to cure.

- Sticks well to many different surfaces, including some hard-to-stick-to materials.

- Rubber-based adhesives provide highly flexible bonds and are usually based on butadiene-styrene, butyl, polyisobutylene or nitrile compounds.

- It can be formulated to adhere at colder temperatures, but there is a limit, and rubber/resin adhesives have limitations at higher temperatures in its basic form.

- Epoxy resins exhibit high strength and low shrinkage during curing and are known for their toughness and resistance to chemical and environmental damages.

When it comes to disadvantages, rubber/resin’s main weakness is that both the rubber and the resin are prone to oxidation from the air. Therefore, exposure to ultraviolet light from the sun and other light sources can break down in heat.

Synthetic Rubber can be used in place of natural rubber. Offering much higher adhesion and shear resistance than natural rubber-based adhesives; as a result, it is very good for sealing packages and cartons.

Acrylic Adhesives Most of the weaknesses of rubber/resin adhesives are overcome by a single component of pressure-sensitive adhesive based on “acrylic” chemistry. Acrylic is colorless and is stable to oxidation and exposure to ultraviolet light. The stability to oxidation can give an acrylic adhesive tape many years of protection against ultraviolet light. However, it is more expensive – about twice as much as rubber/resins; it’s not quite so good as natural rubber on harder-to-adhere surfaces, and it needs significant time to cure.

Silicone-based Adhesives give many years of service life. Like acrylics, silicone can be used against the skin, so it has many medical applications as well as uses in the electrical industry where temperature is a challenge (e.g., jet engines). Silicone adhesives and sealants have a high degree of flexibility and are resistant to very high temperatures. However, silicones are the most expensive adhesives of all, typically twice as much as acrylics.

What are the Advantages of Pressure Sensitive Tape?

Traditional adhesives essentially transform from a liquid form into a solid one to adhere. Those processes are a function of the type of adhesive and how it is engineered to work and for what purpose. The interesting aspect of pressure-sensitive tapes is that they are “just liquid enough” to sufficiently wet the surface the tape contacts.

Conversely, these pressure-sensitive adhesives have enough of a solid-state character to resist any forces trying to remove it. As a result, pressure-sensitive adhesive tapes deliver the ideal means of fastening and offer the following significant advantages:

- Other than ensuring that the surface is clean and dry, there is no preparation necessary.

- Compared with trying to secure something with fasteners such as screws (which can cause various issues depending on the surface to which you need to attach) adhering something with tape can take seconds.

- No special tools are needed, other than something to cut the tape (scissors or a tape dispenser). Many tapes can even be torn by hand. Compared with fasteners such as screws, this is a much easier installation option.

- It isn’t messy to use – there are no brushes or application tools and there is no surplus of adhesive or waste of materials.

- Tape is extremely inexpensive compared to sealants, and provides an incredible number of uses per roll.

- Tape can be applied as a die-cut to the exact area needed, further minimizing waste.

- It is uniform in thickness, giving a precise bond.

- It is instantaneous, which means no waiting for drying or chemical reaction.

- The finished bond is stress-free. All other adhesives create stress in the joint when changing state, which can potentially weaken the bond.

- It comes in many different varieties, some of which are tailor-made to very specific applications.

Why Tape Is Better Than Glue

On a job site full of tools and equipment, the right adhesive tapes can go further than a bucket of screws, for a lot less money. The versatility of adhesive tape makes it a practical substitute to replace traditional fasteners.

- Overall, the most compelling case for using tape over glue is that there’s less mess, and tape takes less time to get the job done.

- Available in a range of widths to suit multiple projects, adhesive tape is rated to support pounds per square inch while varying thicknesses and bonding properties combine to provide construction-strength adhesion for the unique challenges of dissimilar surfaces.

- Many adhesive tapes feature a weather and UV-resistant stick for “tough to adhere to” surfaces like plastic, glass, and wood.

How To Choose the Right Tape

We get this question a lot: How do we actually know that it’s the right tape for the application and that it’s going to last? And that’s totally fair.

Almost everyone we know has a tape failure story, but tape isn’t the same as what you grew up with, or even what you used five years ago. Just as the cell phone in your pocket has gotten smaller, faster and smarter, adhesive technology has gotten stronger and more versatile.

On a job site full of tools and specialty equipment, tape may seem as ubiquitous as a hammer and nails. However, nothing beats tape for versatility, portability, and ease of use… that is IF you have the right tape for the job at hand. And that’s the conundrum, isn’t it? The sheer volume of pressure-sensitive adhesives is so overwhelming that it’s hard to know where to begin.

To help, we’ve created an infographic as a portable field guide for builders and contractors. You can find it here:

What Conditions Make Tape Fail?

When it comes to tape, you may think you can’t believe everything you read. Upon review, a tape’s specification sheet can indicate that its adhesive properties are good, but when you use it, the resulting adhesion is poor.

Of course, when this happens, the tape tends to get the blame. But it isn’t always your tape for example that is at fault. In fact, it may be the surrounding conditions or even the surface that you are trying to stick the tape to.

If you’re facing this challenge, carefully consider every condition that could affect your tape. These can include several variables:

Temperature

Carefully factor in the temperature. Are both the tape and the surface at least 18ºC/65ºF? The tackiness of the adhesive tape is very temperature-dependent, and the colder the conditions, the poorer the bond will be. If you must work at lower temperatures, then use an adhesive tape specifically designed for colder climates.

Related: Why Tape Doesn’t Stick in the Cold

Surface: Is the surface clean? Traces of dust, dirt, grease, and even the slightest trace of moisture will contaminate the adhesive surface and act as a barrier between the two. To best prepare, the surface, give it a quick wash with rubbing alcohol and dry it with a clean cloth.

Uniformity

The typical adhesive tape has a very thin, flat smooth layer of adhesive. Is your surface also flat and smooth, so that the two can uniformly contact one another? If your surface is rough and full of micro “hills and valleys,” the tape can only make contact at the high points – which will result in a weak bond. With a moderately rough surface, you will need a tape with a much thicker adhesive that can fill these valleys, thus providing a major improvement in contact. If it is too rough, then you may need a foam tape with enough deformation to make a good bond.

Chemistry

Is the surface you are working with a plastic or other material? Is it covered with paint or another coating that has a naturally low adhesion or even release quality? Regular adhesive tape won’t stick to waxed surfaces, Teflon®, or silicone, and will even have difficulty sticking to polyethylene. A very tacky tape will help, as well as tapes with an adhesive that is based on natural rubber, but you may need to turn to an adhesive tape specifically designed for your specific surface.

As a very last resort, you may need to change the character of your surface to get an adhesive tape to stick to it. This could mean roughening it with an abrasive or even treating it with a prime coat that is compatible with both the surface and the adhesive.

How To Test Tape

When a customer comes to us with a challenge, we actually test the tape for them and with them.

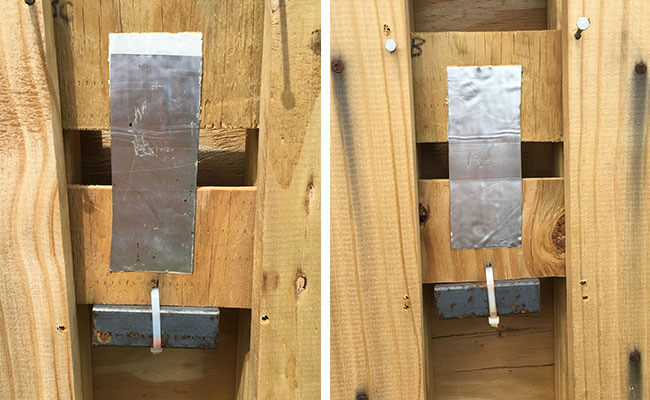

There are two ways to do this: Real-world field testing and lab testing. Ideally, we get to do both, like at The Durability Lab, but the bottom line is that the real world test matters most.

What good is a lab report when your building envelope leaks like a sieve, or your flying splice failed because the adhesive didn’t stick fast enough? Not good at all.

So here we’re going to walk you through the most common tape testing variables we use at ECHOtape.

Know Your Substrate

One of the most critical aspects of our application trials is to test the tape on the actual substrate which is where real-world applications come into play.

For years, lab tape testing was performed on standardized substrates, like steel, and it did not differentiate performance based on a specific material. Over the last five decades, we have learned how critical a factor this is. The tape may work on one specific substrate and fail on others. Sometimes the tape works on a substrate, but when any changes to the chemistry or condition of the substrate change, the tape could end up failing. Even a small change can have a major effect.

Take, for example, splicing tapes. In many situations, customers need a quick stick while materials are still moving (called a flying splice), but then the tape needs to permanently adhere for long-term performance. We first test splicing tape by hand on the substrate — paper, cardboard, flexographic materials — and then see if it pulls fibers. This is good because this shows that the tape has a quick stick. Then, we move it to the actual machine for real-world testing. A splice can take a blink of an eye and so you need to test the tape in the manufacturing process

Permanent or Temporary Bonding?

Which one you want makes a difference in how you test tape. Here are some more behind-the-scenes insights to our application testing process.

For temporary bonding, we are trying to discover whether tape adheres quickly and comes off cleanly..an important field test when considering protective film or stucco tape. In this scenario, we will apply the same environmental conditions to the adhesives, and see how it performs. Does it apply quickly and evenly? Does it remove easily and without residue? We can certainly duplicate this in the lab, but there’s no replacement for real world testing. Which is why it’s important that our clients understand that field tape testing takes time. If your issue is stucco tape isn’t sticking in 90°F and 100% humidity, it doesn’t do us any good to test it in the fall when it’s 60°F and 20% humidity.

Permanent bonding is a different animal. Oftentimes, the tape needs to cure to assess performance, like acrylic adhesives that need 72 hours to set. There are two common real-world tests we use here:

- Shear strength. This is the force pulling down on the tape. To assess shear strength, we can hang a weight and see what happens. Does the tape slide? Where is the force trying to pull it apart? That is what you need to know when you test bonding.

- Peel Strength. Here we measure the degree of adhesion by lifting at 180-degrees, then lifting it the opposite direction. How well does it stick? Does it delaminate, or rip off the substrate? If it delaminates, it means the tape is stronger than the substrate, something you look for when you need extreme bonding power.

Ultraviolet (UV) Exposure and Aging

UV light is a type of electromagnetic radiation, as are radio waves, infrared radiation, X-rays and gamma rays. It’s invisible to the human eye, but it makes a profound effect on adhesives. With prolonged exposure to ultraviolet light, certain chemical materials, such as natural and some synthetic rubbers as well as polyethylene, can experience negative changes to their properties; resulting in them becoming hard and brittle. Absolutely not the qualities you want in a tape that needs to hold for any duration in a particular application. (Read our behind the scenes report on The Durability Lab here.)

The good news is that you can minimize the effects of UV light by choosing the right tape. For outdoor use, it is best to stay away from adhesive tapes with a natural or synthetic rubber adhesive. Unless the adhesive has been specially treated with ultraviolet stabilizers or the backing has an ultraviolet light barrier, like a premium outdoor stucco duct tape. There are also adhesive tapes that have been specially designed for prolonged outdoor exposure typically using an acrylic adhesive.

Extreme Temperatures

We are the leaders in cold weather tape for good reason: our home offices in Canada are ground zero for sub-freezing environmental conditions.

It doesn’t get any more real than that.

Still, we do also conduct lab testing. Using a temperature-controlled, environmental chamber, we bring temperatures down below -30°F and assess the outcome. Does it stick, and does it stay secure? The same is true for heat, although real-world tape testing is done in Arizona, Florida, and Texas.

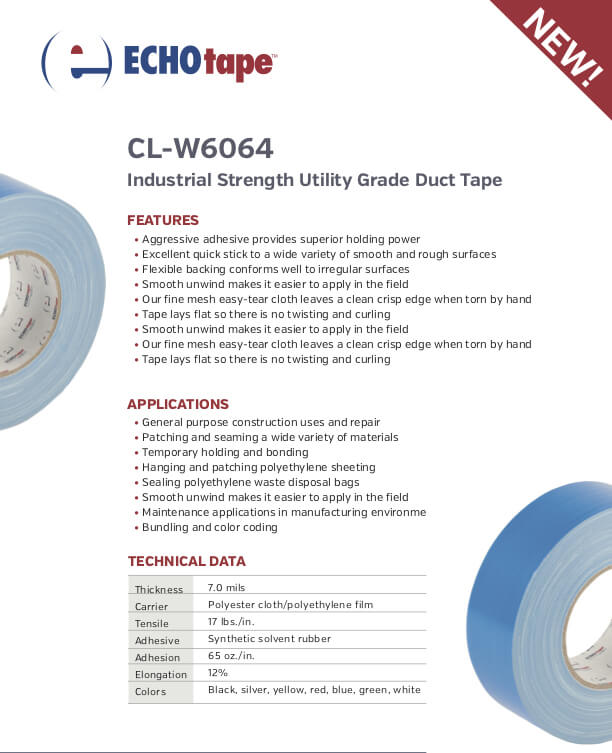

How To Understand An Adhesive Tape Spec Sheet

How To Understand An Adhesive Tape Spec Sheet

For engineers and general contractors, both the tape sample and the specification sheet should be closely reviewed when considering their uses. But what detail does the specification sheet provide and how can the maximum benefit be derived? Here’s what you need to look for, whether it’s high-bond foam tape, stucco tape or industrial-strength construction-grade duct tape:

- Construction properties: The specification sheet will initially provide an accurate verbal description of the tape’s construction as well as a summary of its properties. By this information alone, you will know whether or not this is the kind of tape needed.

- Versatility: Adhesive tape is highly versatile, and any individual tape can prove to have many other uses than were intended when it was first designed. A pressure-sensitive tape consists of one or more soft amorphous broad molecular weight polymers and often contains several other chemicals. Because of this, even though it is manufactured to tight quality-control specifications, it can’t be manufactured to the precision expected of an accurately machined metal part.

- Adhesive type: A natural rubber-based system is the general-purpose workhorse type of tape, but if you have special needs from your tape – such as long-term aging, resistance to ultraviolet light, or non-corrosive properties – you will need to look for the higher performance acrylic. The adhesion level quoted is determined in a test environment (on a steel surface) in a very specific way, so your own end-use probably won’t duplicate this. But the specifications should serve as a helpful guide to what level of adhesion you can expect when compared to the adhesion quotes of other tapes.

- Tensile strength and elongation information: The relationship between the tensile strength quoted and its elongation is far from linear, but you can get a rough estimate of the elongation expected when the typical slight application tensile force of less than a pound or two is applied to the tape. With plastic films, this stretch will be elastic and the tape will want to recover, but with paper, it will be “dead stretch” with no recovery.

- Temperature limits: Where the tape is intended for a higher temperature operation, the upper temperature limit will be quoted. Note however there is no tolerance with the upper working temperature, so the tape should not be used above this quote.

- Resistance to shear: The resistance to shear (minimized effect of adhesive bleed or the “oozing” of adhesive beyond the tape) will also be given when it is key to good performance.

What is Adhesion Value, Exactly?

Tapes are often rated by adhesion value, which can be helpful if you know what it means. Here are a few examples:

- Looking for a removable tape? You definitely need low adhesion. A protective tape offers the lowest adhesion – at around 10 ounces per inch – while a masking tape would be around 25-35 ounces per inch.

- A more difficult surface? You will need a higher adhesion level, perhaps even up to 45-60 ounces per inch. Additionally, if the tape is for a permanent application, it will usually call for a high adhesion value.

- If the use is both permanent and on a porous surface, such as corrugated cardboard, then as long as the adhesive strength of the tape to the cardboard is higher than the internal strength of the cardboard (as evidenced by the tape tearing the surface of the cardboard), there is ample adhesion for the job – making adhesions of 60-100 ounces per inch totally unnecessary.

- If the tape is for a rough surface, it means that the adhesive contact could be poor. So it may not be a high adhesion tape that is needed, but one with a thicker adhesive to better contact the surface. Similarly, a tackier tape might work better on a hard-to-adhere surface than one with a higher adhesion.

Tensile Force vs. Shear Force

When it comes to determining if a particular tape is right for your construction project, there are two forces to consider: tensile force and shear force.

Tensile force influences the elastic property of the adhesive. Specifically, it will first stretch the adhesive before finally pulling it away from the surface. If a tensile force causes a failure, it will most likely be in the adhesive at the surface. Therefore, adhesion testing that measures the elastic character of the adhesive, and how much force it can take, will help you select the right tape.

A shear force works parallel to the surface – it is the major force at work in double-sided tapes. Shear force resistance testing – often called “Holding Power” – is an effective way to measure the internal strength of the adhesive (known as “cohesion”).

Most adhesive failures or separation occur as a combination of both tensile and shear forces, it is extremely helpful to know what forces could potentially affect your tape.

Keep in mind that if the outside force is large enough, and is continuously applied, all tapes will eventually fail. It’s not a matter of “if,” but “when” – it may take an hour, a week, a year, or more, but if a tape isn’t designed to withstand the outside forces, it will eventually fail.

Release Liners: What Are They and Why Do You Need Them?

For tape, because of how it is dispensed, the adhesive part must contact its own backing yet still be able to unwind easily. To achieve this, the backing must provide a low-adhesion release surface. In other words…not stick to itself!

- Paper tapes need a coating known as backsize, as well as a low-surface energy coating known as a release coat. Plastic films only require a release coat.

- The backing on foam tape won’t allow the adhesive to come in contact with it

- For aluminum foil tapes, the act of unwinding it from its own backing will cause it to ripple and distort the foil, which will adversely affect the contact area as well as the appearance.

For all of the above, the best solution is to use a facing material with a low surface energy, usually a paper or a plastic film that has been treated with a silicone release coat. They could also be a polyethylene film that already has a low enough surface energy to work as release facing, or even a silicone-coated polyester film.

Adhesive Tape is a Universal Tool

In short, pressure-sensitive adhesive tape is the industrialist’s dream come true. It is the universal tool that simply and conveniently solves many different fastening challenges. These tapes come in a wide variety of backings, each suitable for specific end-uses. This is exactly why adhesive tape use is on the rise in high-performance building and construction. If you’re still using glues, sealants or even nails, consider pressure-sensitive tape.

Contact the ECHOtape team today to find the right tape for your application.

Related:

How To Understand An Adhesive Tape Spec Sheet

How To Understand An Adhesive Tape Spec Sheet