Fiberglass is a popular choice for insulation but it’s not a one-size-fits-all solution. Understanding its specific properties as well as its strengths and drawbacks can go a long way towards making the right insulation choice for your metal building needs.

Let’s examine some common myths and misconceptions about fiberglass insulation.

MYTH 1: Moisture does not impact the effectiveness of fiberglass insulation.

Fiberglass is an example of open-cell insulation. It works in much the same way as materials like Styrofoam, Gore-Tex, and neoprene. The woven fiber strands contain hundreds of small air pockets, which provide the insulation. If it is exposed to moisture, those little pockets will fill up with water (instead of air) and lose its ability to produce any kind of insulation. Therefore, if fiberglass insulation becomes wet, its performance is compromised, but in many cases, it will regain its effectiveness as the material dries out.

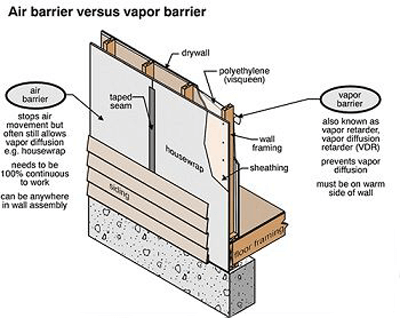

Since metal buildings do not have vapor barriers on the exterior walls, the fiberglass insulation needs to come with its own laminated facing. There are several types of facing to choose from and it largely depends on the level of workability, permeability, and durability you need for your building. You can find out more by reading our Field Guide to Insulation for Metal Buildings.

MYTH 2: Cramming extra fiberglass rolls into a small space will increase the R-value.

The question you are really asking is: Does Adding More Rolls of Insulation Increase the R-value? And the answer is no. While it is true that doubling up rigid foam board insulation will increase its R-value, the same does not hold true for rolls of fiberglass. As mentioned above, fiberglass relies on small pockets of air in order to provide insulation. If those pockets are compressed than they can’t hold as much air. Hence compressed fiberglass is not as effective, and the R-value is reduced.

MYTH 3: A high R-value guarantees good insulation.

R-value, or the ability to resist heat flow, is a standard metric used by all manufacturers and industries. The common perception is that the higher the R-value, the better (and more expensive) the insulation. But as we’ve learned above, there are certain conditions that can cause fiberglass rolls to lose their R-value. Proper installation techniques are just as important as choosing a material with a high R-value. This includes using the right adhesive to protect the laminated fiberglass from any tears, splices, or cutouts around plumbing and electrical fixtures, choosing a reflective facing rather than a roll that’s more the 4 inches thick, and making sure the fiberglass fits properly into tight or unusually-shaped spaces.

MYTH 4: Fiberglass is not a “green” insulation material.

In the current trend towards green and sustainable building, fiberglass is left out of the conversation. That’s due to two factors; 1. fiberglass is a man-made material (unlike cellulose or sheep’s wool) or 2. some believe it poses a health risk. But did you know that fiberglass is made from secondary sources (up to 50%-70% recycled glass) so it diverts materials from landfills? And unlike the more popular green alternative, cellulose, it poses no fire hazard. Cellulose has to be treated with chemicals in order to make it flame and critter resistant.

MYTH 5: Fiberglass poses a health risk

It’s true that fiberglass can irritate the eyes, skin, or respiratory system. But that’s only if the material is improperly handled at installation. Rest assured that a professional will always use protective gear such as safety goggles, gloves, and a mask to avoid these risks.

There has also been much speculation as to whether fiberglass causes cancer. In 1987 the International Agency for Research on Cancer identified all man-made vitreous fibers as possible carcinogens. This is what led to those warning labels on fiberglass. However, after much international scientific research, they reversed their decision in 2001. And in 2011 the National Toxicology Program officially removed fiberglass from its list of “Reasonably Anticipated to Be Carcinogens”.

Two Great Reason to Insulate Metal Buildings

When designing a metal building, is insulation really necessary? Aren’t metal buildings known for their durability and low maintenance?

Yes, and yes.

When it comes to metal buildings, insulation addresses two important goals—stabilizing the structure’s interior temperature and preventing moisture from entering or collecting via condensation.

At ECHOtape, we offer a full range of specialty insulation tapes specifically designed for metal building and metal building insulation.

To learn more about adhesive tape, refer to our Technical Guide to Adhesive Tape. Or, contact the ECHOtape team with your tape request if you want help determining which product is best for your particular project.