In just about every climate in which we live and build, the No. 1 job of any building enclosure is environmental separation.

Keeping water, air, and heat locked in or out of buildings can make them more resource-efficient, durable, and safer for occupants.

The greatest challenge in this endeavor is maintaining the continuity of our air barriers, drainage planes, and insulation layers, particularly at penetrations, transitions, and margins of building assemblies.

The answer?

High-performance seaming tape.

Seaming Tape — A Brief History

In the early 1970s, residential builders knew almost nothing about airtightness and air movement. Even engineers were ignorant about hot and cold air leakage in buildings because the basic research hadn’t been done yet.

It wasn’t until the late ‘70s when the first residential air barriers were installed in Saskatchewan that pioneering Canadian builders began sealing the seams of interior polyethylene sheeting with Tremco acoustical sealant. (The first seaming tape, if you will.) The results were self-evident, and since then, most North American building codes now require builders to include details designed to reduce air leakage.

The same holds true in Europe, where using tape to seal the building envelope is the standard operating procedure in passive house (a.k.a. Passivhaus) construction. Passive Haus results in ultra-low energy buildings that require little energy for space heating or cooling.

In fact, tape experts cite Europe as the best example of the overall utilization of acrylic tapes in construction. “In Europe, they tape up everything when building or retrofitting to create an air-tight seal,” says David Joyce, nationally known construction and tape expert, and owner of Synergy Companies Construction LLC. “Energy costs are much higher there, and it’s a matter of necessity.” Joyce notes that the industry here in the U.S. “is just recently becoming more aware of the benefits of air-tight building practices and that acrylic tapes make that much easier.”

It’s easy to see why the practice of seaming is seeing a surge among insulation professionals: The energy benefits of air barriers are huge.

A 2005 study from the National Institute of Standards and Technology, “Investigation of the Impact of Commercial Building Envelope Airtightness on HVAC Energy Use” by Steven Emmerich and others, found that just incorporating an air barrier in a building can reduce its heating and cooling cost by up to 36%.

Furthermore, uncontrolled air leakage could have consequences beyond increased energy consumption, regarding health and safety of the building occupants, as well as premature deterioration of building materials.

Additionally, the International Energy Conservation Code (IECC) and several state energy codes now require the use of air barriers. In addition, a growing number of municipal authorities having jurisdiction (AHJs) and green-building trade groups are calling for their use. Some federal agencies and large owner and developer groups also require them.

More importantly, energy efficiency and occupant comfort—two key ingredients of sustainable design—are driving the use of air barriers across market sectors. With today’s high cost of energy and concerns about Indoor Environmental Quality (IEQ), air barriers are one of several construction systems with a critical role to play.

As our building profession evolves to becomes more energy-efficient, more sustainable, and more “green”, air sealing every building is going to become the norm. And, of course, more tape will be used to do this.

Benefits of Seaming Tape in High-Performance Building

There are three primary drivers for the increased usage of seaming tapes on job sites:

- More stringent codes. Increased building envelope requirements — air and moisture control layers;

- Improved tape technology.

- Heightened awareness of the high-value seaming tape by builders, contractors, and building scientists.

Don’t just take our word for it. Consider this direct quote from Building Energy Code Resource Guide

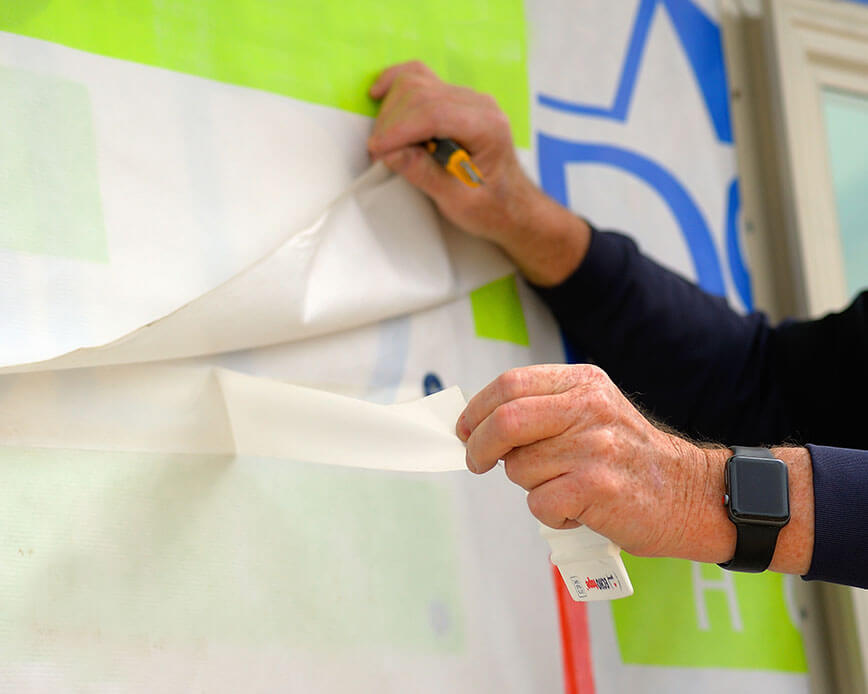

To limit air leakage, builders use tapes to seal the seams of a variety of membranes and buildings products, including housewrap, polyethylene, OSB, and plywood. Tapes are also used to seal duct seams, to seal leaks around penetrations through air barriers — for example, to seal around plumbing vents — and to seal sheet goods to a variety of materials, including concrete.

“Tapes have become much more commonplace in the construction industry today than they were 10 years ago,” Joyce says. “And they’re going to become more and more so as air sealing, energy efficiency and durability become more important, and builders are becoming more educated about the benefits of tapes over other sealants or flashing materials.”

Indeed, trend reports indicate that overall, tapes used on job-sites will outpace the overall construction industry growth (3%-5%) with an estimated 6%-7% annual growth rate. New residential tape use will increase the fastest in double digits due to code compliance. In the past, tapes were used sparingly on joists and viewed as a temporary fix or cheap solution.

Today, tapes have transitioned into high value and highly functional products that enhance building airtightness, prevent water intrusion, and even increased roof safety and integrity in high wind events.

While no single tape works well in every air sealing application, there are four common benefits worth considering:

- Seaming tape is very easy to use.

- In context to other building materials, tape is inexpensive.

- Effective air sealing — air control, moisture control, and “protection” of finished materials — depends on both the materials being used (what are you taping?) and what are the conditions (in heat, in cold, etc.). There are a lot of tapes available so you can match the conditions with the situation.

- Tape can create a continuous barrier when applied correctly, which is what you need an air seal to be for it to be effective. This is hard to get with other kinds of fastening systems.

Today’s newer and higher-performing adhesive tapes offer builders better choices and multiple advantages over conventional building materials. These tapes actually stick better over time, are more durable, and are more weather resistant. Indeed, modern adhesive technology is much more sophisticated as a whole.

The Next Generation of Seaming Tape

When it comes to choosing the best construction tape, the maxim that “if it ain’t broke, don’t fix it” doesn’t cut it. High-performance construction tapes will become more important as the construction industry deals with stricter regulations and as best practices in the industry change with the times. To stay ahead of these changes, and meet the needs of high-performance builders across North America, we’ve recently launched a new seaming tape that uses advanced adhesive technology to stick to just about anything

PE-M4535 is a next-generation seaming tape for the construction professional looking for superior performance. Formulated with a proprietary cold weather adhesive —excellent cold climate adhesion to -4°F! — PE-M4535 is engineered to adhere to a wide range of building materials and surfaces. Made from an advanced polyester backing, it is extremely strong, yet can still be torn by hand, which makes it easy to apply.

Highly adaptable and versatile, PE-M4535 can be used in a wide variety of building envelope sealing applications, such as:

- House wrap

- Insulation, including polysio-cyanurate and reflective insulation

- Exterior sheathing

- Vapor barriers, including polyethylene films

- Flooring and roofing underlayments

At ECHOtape, we’re focused on generating real-world adhesive solutions that help Building and Construction professionals work more efficiently and cost-effectively on every job site. It’s why we’ve engineered such an extensive line of durable, resilient, weather-resistant construction tapes, including seaming tape, insulation tape, foil tape, stucco tapes, cold weather tape and more. So, no matter what project comes your way, the quality and reliability of your work are guaranteed.