Let’s dispel the myth that metal buildings are for short-term use only.

The truth is quite the opposite.

Long a standard for warehouses, distribution centers and industrial facilities, metal building has evolved to include commercial office buildings, retail storefronts, and even residences.

Why?

Because metal structures are increasingly recognized as reliable, sustainable, energy-efficient, and cost-effective… if they are insulated properly.

When designing a metal building, it may be tempting to skip the insulation. Is insulation really necessary? Aren’t metal buildings known for their durability and low maintenance? What seems like an easy cost-cutting strategy today can actually create more problems down the road. Read on to learn more about metal building insulation.

Top Reasons to Insulate Metal Buildings

When designing a metal building, it may be tempting for builders and contractors to skip the insulation.

Is insulation really necessary? Aren’t metal buildings known for their durability and low maintenance?

Well, yes.

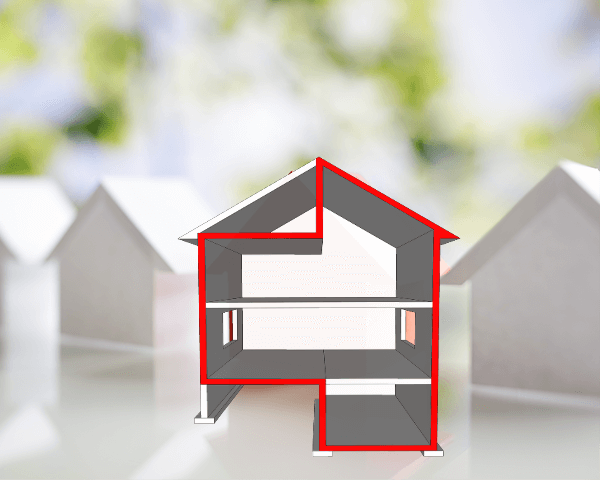

When it comes to metal buildings, insulation addresses two important goals—stabilizing the structure’s interior temperature and preventing moisture from entering or collecting via condensation.

When it comes to temperature, insulating metal buildings is essential because metal is a far better heat conductor than wood. Meaning things get hotter, or colder, faster. By controlling the heat transfer rate throughout the building with insulation, temperature fluctuations are better managed and energy usage is reduced.

As for moisture, when temperatures vary noticeably between outside and in, condensation will form. Moisture allows unhealthy mildew and mold to grow, particularly harmful to people with allergies. Without proper building maintenance practices, moisture can also cause building rust and corrosion—something no home- or business-owner wants.

To offset this, most fiberglass insulation includes a vapor retarder, which is a facing that prevents or slows the flow of moisture through to the insulation it is attached to. A low “permeance” indicates a superior vapor retarder. Also, vapor retarders are typically required to be fire retardant.

But wait, there’s more!

Depending on how the structure will be used and where it will be situated, noise may be cause for concern. For example, if the structure will be used as a club or event forum, it may be beneficial to consider the sound implications the building’s usage could have on adjacent properties.

Proper insulation will limit noise pollution (and unhappy neighbors). Insulation also has the ability to absorb interior sounds that reverberate through the building. Which is especially helpful if you have loud machinery running all day.

Another advantage of insulating a building is that it prevents unwanted critters from entering the property. Insulation has proven to be a major deterrent to rodents and birds. By protecting every crevice of your building you leave little ability for wildlife to encroach.

All told, good metal building insulation will have the following benefits/features:

- High R-value (thermal break)

- Eliminate condensation

- Radiant heat barrier

- Not be affected by humidity

- Vapor barrier

- Install easily

- Not allow nesting for rodents, birds or bugs

- Recognized by ICCES and Qualified by Energy Star

Types of Fiberglass Insulation

Today, there is a variety of building insulation material options available, and new technologies, as well as long-forgotten ideas, are coming to public attention as thermal resistance and energy savings become more of a concern in green building design.

For our purposes, the most common types of insulation found in metal or steel buildings is fiberglass, and it’s available in several forms:

• Blanket (often called rolls or batting): Mineral fibers of rock wool or processed fiberglass make up batt and blanket insulation. Batt is very inexpensive but it must be installed carefully for full effectiveness. Some versions have a radiant barrier backing, the best type for metal buildings. Blanket insulation is a rolled insulation cut to specific widths and lengths. Both batt and blanket have R-values of R-3 per inch. Both batt and blanket insulation are inexpensive, and widely available at virtually any big box store, making it ubiquitous on job sites from coast to coast. Since metal buildings do not have vapor barriers, you will need to choose blanket insulation with a laminated facing.

• Loose fill is insulation made up of loose fibers or fiber pellets. The insulation is blown into building cavities rather like shooting water from a hose. It can be more costly than other types of insulation, but it can get blown into corners and places where a blanket might not fit. It can also be installed without disturbing frames or finishes.

• Foam “rigid boards” are good for any climate, withstanding even the highest of temperatures. Typically made of polyurethane, fiberglass, or polystyrene, this kind of insulation is available in a variety of performance ratings and can be very effective for dampening noise as well as resisting heat and moisture. The R-value can range from R-4 to R-8 depending on the thickness of the cut.

It’s relatively easy for a non-professional to install. If you plan to use this type of insulation, be sure to let your metal building provider know so that the proper accommodations can be made, such as longer fasteners and extended panel lengths.

That said: Fiberglass is not impervious to water. In fact, it will lose the effectiveness of its insulation properties if exposed to moisture. To prevent this from happening, facing materials are laminated to rolls or batts of fiberglass to serve as a vapor barrier (or vapor retarder). The facing material acts as a vapor barrier or vapor retarder and protects the insulation from moisture. The fiberglass R-value (or the ability to resist heat flow) depends on its thickness.

However, it will lose the effectiveness of its R-value if exposed to moisture. Why?

Fiberglass rolls or batts are an example of open cell insulation. The woven fiber strands contain hundreds are air pockets and air, as we all know, is an excellent insulator. Once those air pockets are filled with moisture the fiberglass loses its ability to act as an insulator. (Along the same lines, fiberglass also loses part of its R-value if it becomes compressed as there are fewer and fewer air pockets to act as insulation.)

And that’s just the tip of the iceberg. Moisture damage can also lead to mold growth and rust damage, which will mean extensive, time-consuming repairs to your facility.

It is possible to restore the fiberglass if you are able to let it dry out thoroughly and ascertain that is has recovered its full thickness. But a more effective approach would be to seal the vapor barrier properly in the first place. [You can reach more about fiberglass insulation myths here.]

Moisture has the opportunity to get in where there are:

- holes or tears in the facing

- insulation splices have not been properly made

- inadequate sealing around things like plumbing and electrical fixtures

Using the right adhesive may seem like the least important detail in the grand scheme of the building’s construction. But it is, in fact, the critical link in sustainable metal building. Without proper sealing, your insulation loses its effectiveness.

With poor insulation, your utility costs go up and you risk significant long-term damage to your building or the equipment and property inside. And no one wants to deal with problems of that magnitude, especially when they can be easily avoided.

4 Benefits of Metal Building Insulation

Since the introduction of fiberglass insulation in 1938, it has remained the preeminent insulation material for commercial and residential construction. Over the years, fiberglass insulation has proven its ability to make buildings more energy efficient, reduce utility costs and increase occupant comfort. These and other important attributes have given it a new life as the leading insulation material in many of today’s green building projects.

Here’s why:

1. Moisture Resistance

When exposed to moisture, fiberglass insulation neither absorbs nor holds water. If fiberglass insulation does get wet during or after installation, installers should visually inspect it on all six sides for contamination.

If the material appears free of visible defects, installers must dry it thoroughly to restore its full R-Value. Once the area surrounding the insulation has also been inspected, cleaned and fully dried, the fiberglass insulation can be reinstalled and will regain its original R-Value1.

It is important to note that fiberglass insulation must have a vapor barrier in order to be effective. All condensation should collect between the exterior wall and the vapor barrier because exposure to moisture decreases the effectiveness of fiberglass insulation. In order to prevent this from happening it is important to choose a vapor barrier with a sufficient perm rating and to make sure the barrier is properly sealed with the right adhesive to prevent leakage.

2. Fire Resistance

Made from sand and recycled glass, fiberglass insulation is naturally noncombustible and remains so for the product’s life. It requires no additional fire-retardant chemical treatments.

Many building codes also recognize fiberglass insulation as an acceptable fire stop in wood- and steel-framed wall assemblies.

3. Acoustic Control

Fiberglass insulation is a naturally sound-absorbent material that significantly reduces sound transmission in wall, ceiling, floor and HVAC assemblies. The first inch of fiberglass insulation in a building cavity can increase an assembly’s sound transmission class (STC) value by three or four points in some constructions. Each additional inch can further increase the STC rating by two points2.

4. Recycled Content

Between 1992 and 2000, the fiberglass insulation manufacturing industry recycled more than 8 billion pounds (3.6 billion kg) of pre- and post-consumer glass containers, eliminating the need for millions of cubic feet of landfill space3.

Fiberglass insulation has significant recycled content, with some batt, roll and loose-fill insulation products containing up to 80 percent recycled glass4. The other main ingredient in fiberglass insulation, silica sand, is an abundant, naturally renewing resource, limiting environmental impact in the manufacturing process

Fiberglass insulation packs multiple green performance features into one product and still comes at a very competitive price when compared to other insulation materials. After 70 years on the market, it’s an excellent choice with a tried-and-true track record. As part of this growing market, we provide a variety of insulation tapes and protective films, perfect for metal building construction professionals.

How to Choose the Best Fiberglass Insulation Facings

Most insulation facings used in metal buildings are available in only two color finishes–white or black.

White facing has been specifically designed to provide the inside with a bright, finished look since metal buildings typically do not have an interior wall material (such as sheetrock).

Black facings are primarily used for areas such as roofs or ceilings that shouldn’t be the focus of attention as it is more cost-effective to use this than to paint white material.

There are several options on the market and each will have its own detailed spec sheet. But the three main factors to consider are:

- Workability: temperature conditions for installation

- Permeability: the rate at which water vapor will pass through

- Durability: how well it will stand up to physical stress without ripping or tearing

The most popular insulation facings are from Alpha, E& H and Lamtec, such as WMP®-VR, a white polypropylene reinforced facing which is excellent for chemically hostile environments; or WMP®-VR-R, which is recommended for use in high-humidity interior conditions where walls are exposed to heavy traffic. One of our favorites is WMP®-50, twice as strong as WMP®-VR-R and extremely workable in freezing conditions up to -40º F.

As always, you want to always make sure that you select the right ECHOtape insulation tape to seam any of these.

How to Make Your Metal Building More Efficient

As more and more architects and builders embrace the clear benefits of using metal as a building material, so goes the attention to its unique insulation requirements. For all its well-known advantages, metal is not exempt from the need for the same good insulation practices like any other structure. Following the best practices outlined above will help, as will sealing leaks and seaming sections with tape.

Keep the following tips in mind:

- To yield the best result for metal building insulation, a heavy-duty thermal insulation tape will help form the essential vapor barrier. The prevention of thermal energy loss is the outcome when correctly installing insulation.

- For metal buildings erected in areas that suffer extreme temperatures, an insulation tape with aluminum foil coating designed to adhere to temperatures at either end of the spectrum – including cold weather – is the solution.

- Double Coated Tape with high a high-performance adhesive is invaluable in the overall effort to brace a building to endure the elements.

All told, more and more architects, contractors and designers are discovering the advantages of metal building solutions.

For design alternatives, efficiency, durability and sustainability in support of LEED efforts, metal is unlike any other. It ages much more gracefully than traditional construction materials. It doesn’t crumble, its foundations don’t squeak, its walls don’t expand and warp. When its envelope is properly sealed, metal will just march on; proving a sound structure and investment for decades to come.