Is it an air barrier? Or is it a vapor barrier?

Are you sure? Although both are extremely important components of high-performance buildings, the two are not the same.

With very different functions to perform in the building assembly, understanding the core differences between air barriers and vapor barriers are paramount to building the high performing homes of the future.

Here’s what you need to know about air barriers vs. vapor barriers.

What Is An Air Barrier?

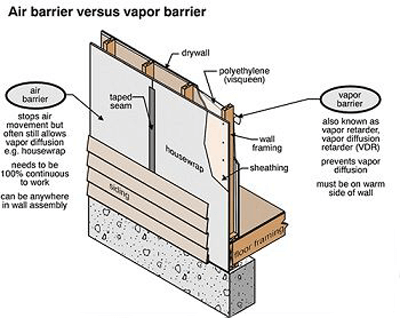

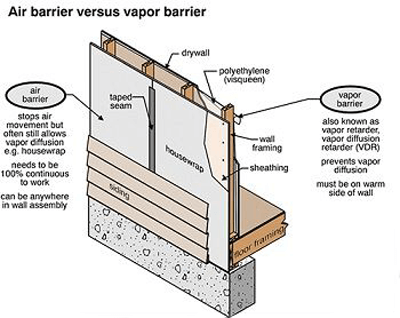

Air barriers are systems of materials designed and constructed to control airflow between a conditioned (indoor) space and an unconditioned (outdoor) space.

Air barriers can be mechanically fastened building wraps, adhesive membranes, fluid-applied materials, insulating board stock, non-insulating board stock, spray polyurethane foam, poured concrete, metal, glass, and a host of other materials.

But no matter what material you choose, all air barriers should be:

- impermeable to air flow;

- continuous over the entire building enclosure or continuous over the enclosure of any given unit;

- able to withstand the forces that may act on them during and after construction;

- durable over the expected lifetime of the building.

Keep in mind there are two kinds of air barriers – interior and exterior – and while both serve similar purposes, each complements and/or enhances the effectiveness of the other. Interior air barriers control leakage of a home’s interior air into the wall cavity and attic, limit the ability of moist indoor air to enter the wall cavity during the heating season, and limit convection losses within walls.

Exterior air barriers control infiltration of exterior air into the wall cavity and through the attic, limit the ability of moist outdoor air to enter the wall cavity during the cooling season, and prevent wind-washing of wall insulation (i.e., even though a house tests tight on the interior, it could have a leaky exterior wall and top plate that cause big energy losses). It’s a good idea to install both types of air barrier so as not to negate the benefits of one by neglecting the other.

Related: learn more about building envelopes and why they matter

What Is A Vapor Barrier?

Vapor barriers (or vapor retarders) are materials used to slow or reduce the movement of water vapor through a material. Vapor barrier materials are installed on the warm side of the insulation in a building assembly, as determined by climatic conditions. In warm climates, it will be on the exterior and in cold climates, it will be on the interior.

A vapor barrier can be a mechanically fastened sheet-material, adhesive membranes (depending on composition), fluid-applied materials, insulating board stock or medium density spray polyurethane foam. The thickness of the material will impact whether it is a vapor barrier or not.

But Wait… There’s More

Here’s where things can get confusing. Water vapor may be transported by air leakage, but you address this issue by installing a proper air barrier, not by a vapor barrier.

Vapor barriers are intended to control the rate of diffusion into a building assembly. Therefore, the vapor barrier does not have to be continuous, does not have to be free of holes, does not have to be lapped, does not have to be sealed, etc. A hole for example in a vapor barrier will simply mean that there will be more vapor diffusion in that area compared to the other areas of the vapor barrier.

To simplify, consider this wool sweater analogy: A wool sweater is insulation. It will keep you warm when there is no air movement, but it still allows the wind to move right through it.

A wool sweater with a raincoat will keep you warm, but hold moisture inside and soak your insulation. A wool sweater with a windbreaker will keep you warm, stop the wind from stealing your heat, yet allow moisture to diffuse through it.

So think of a windbreaker as an air barrier and a raincoat as a vapor barrier.

In high-performance buildings, air barriers and vapor barriers, as well as water-resistive barriers, can be combined. There are also vapor-permeable air barriers, and there are water resistive barriers which are not air barriers.

It’s important to understand the separate functions and then determine whether the material provides more than one function. As an example, you can have two, three or even four air barrier materials in a wall assembly, but its effectiveness will depend on which material you have chosen and how you have connected the air barrier materials together.

Why Do Air Barriers Really Matter?

For one, air pressure and moisture control in buildings have become a very important element in constructing durable and energy-efficient structures.

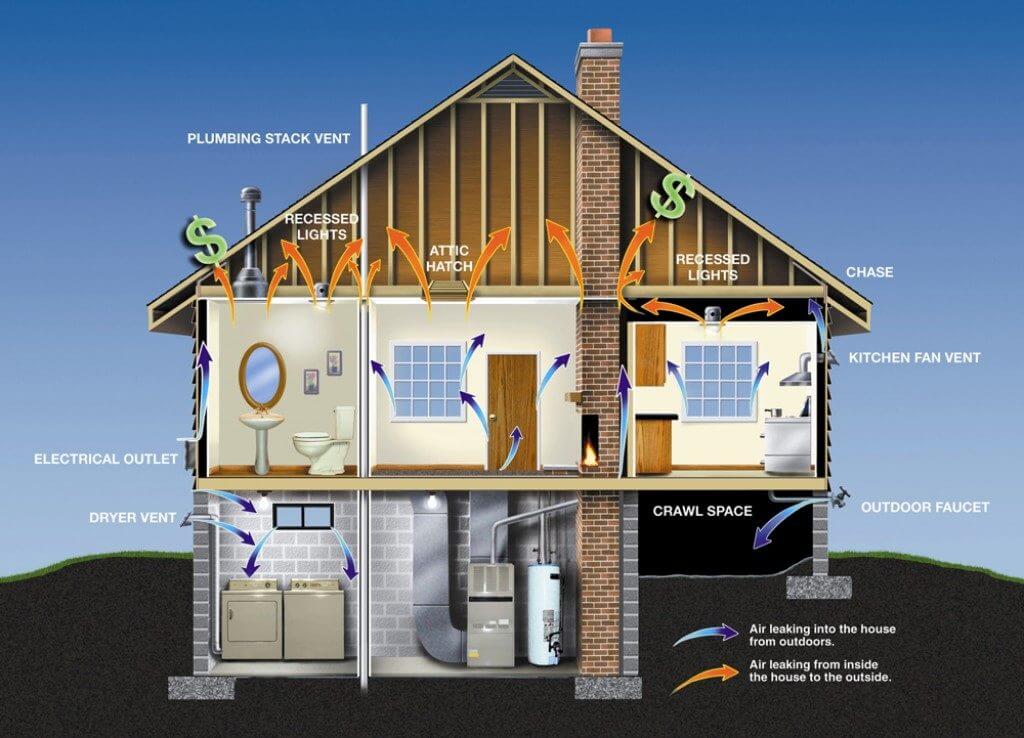

Air leaks can cause havoc because air not only short circuits insulation, but air is a “carrier” for unwanted elements inside a home (i.e. noise, dust, vapor and heat/cold). When there is uncontrolled air movement from outside to inside (and visa versa), there is an increased risk for building failure or lackluster performance. Moisture in all three states (vapor, liquid, solid) is a hazard to a building.

Additionally, the International Energy Conservation Code (IECC) and several state energy codes now require the use of air barriers in building codes. In addition, a growing number of municipal authorities having jurisdiction (AHJs) and green-building trade groups are calling for their use. Some federal agencies and large owner and developer groups also require them.

More important, energy efficiency and occupant comfort—two key ingredients of sustainable design—are driving the use of air barriers across market sectors. Consider this:

39 quadrillion British thermal units (BTUs). According to the U.S. Energy Information Administration (EIA), that’s how much energy was consumed by all the residential and commercial buildings in the United States in 2015. Those BTUs represent approximately 40 percent of all the energy consumed nationwide. Concurrently, these structures account for about 38 percent of all CO2 emissions in the country.

This statistic comes from a blog post by our friends over at Barricade Building Products. Like us, they are diligently working on new product innovation addressing the rapidly changing needs of high-performance building products.

Choosing the right house wrap is much like choosing the right tape. With today’s high cost of energy and concerns about Indoor Environmental Quality (IEQ), air barriers are one of several construction systems with a critical role to play.

In order to design and build safe, healthy, durable, comfortable and economical buildings airflow must be controlled. Airflow carries moisture that impacts a building material’s long-term performance, integrity and durability, behavior in fire (spread of smoke), indoor air quality (distribution of pollutants and location of microbial reservoirs) and thermal energy. One of the key strategies in the control of airflow is the use of air barriers.

By essentially “wrapping” the building shell, air barriers (a.k.a. air sealing) ensure that the building is protected from the effects of airflow and air leakage. Here are four tangible benefits to air barriers:

1. Preventing the Loss of Conditioned Air

For most consumers, the biggest reason “why” is air barriers are important is comfort.

In summer, we normally cool and dehumidify the air to a lower temperature and humidity than the exterior environment. In winter, we typically heat and humidify the air to a higher temperature and humidity than the exterior.

Controlling interior temperature is paramount to comfort. The United States Department of Energy reports that over 30 – 40 percent of the cost of heating and cooling a home is lost to uncontrolled air leakage. This can hamper the performance of other building systems such as insulation and HVAC.

Proper air sealing helps reduce uncomfortable temperature fluctuations and often allows for smaller, more efficient HVAC equipment.

2. Lower Utility Bills

Maintaining conditioned air means less energy is needed to recondition the air. Less energy means lower utility bills. And since all building systems must perform well together to optimize the energy efficiency of a home, the savings can add up.

Buildings which have a properly installed air barrier system can operate properly with a smaller HVAC system as the mechanical engineer does not have to compensate for a leaky building. In some cases, the reduction in mechanical equipment size and cost can also offset the cost of the air barrier system in addition to lowering utility bills.

3. Preventing Moisture

Wherever air moves, water vapor can follow. Proper air sealing reduces the risk of water vapor moving into the wall system where prolonged exposure can result in moisture issues such as wood rotting and mold, which can cause expensive structural or health problems. Air leakage has the ability to transport exponentially more moisture into and through the building enclosure than occurs through vapor diffusion alone.

4. Improved Indoor Air Quality

Air barrier systems help keep out pollutants such as suspended particulates, dust, allergens, insects, odors, noise and more.

Lastly, it’s important to note that the International Energy Conservation Code (IECC), the DOE Zero Energy Ready Home program and several state energy codes (see California Title 24) now require the use of air barriers.

In addition, a growing number of municipal authorities having jurisdiction (AHJs) and green-building trade groups are calling for their use. Some federal agencies and large owner and developer groups also require them.

It’s no longer a question of should you use an air barrier, but how to design and install high-performance air barriers that will stand the test of time. Be sure to look at ECHOtape’s collection of seaming tape.

Don’t see something that meets your specific needs? Let us help! We love solving tape challenges.