In this comprehensive guide to all things double-sided tape, we’re giving you all the information you need to know about choosing and using double-sided tape in seaming, splicing, bonding and beyond.

What is Double Sided Tape?

Created by applying a thin adhesive layer to each side of a carrier substrate material, double-sided tape, also known as double-coated tape or double-faced tape, is widely used by a vast array of industries for applications such as bonding, holding, mounting, splicing, and packaging. Obviously, it is most often used to stick two surfaces together; typically in a way not visible in the end product. This is due to it being installed “in-between” rather than “overlaying upon” in use. This specific application allows for a neater look and better craftsmanship.

Double-sided tape can be either thin (such as paper-based) or thick (such as foam-based), coated with rubber, acrylic, or a modified version of these sometimes with differential properties. Double-sided tapes with thick bonding systems are usually better able to bond to unusual, non-uniform, or highly patterned and textured surfaces. Thick bonding systems usually involve a foam carrier layer and may vary significantly in strength. Thin bonding systems are, as the name suggests, much thinner – sometimes so thin that they consist of nothing but pure adhesive on a silicone liner. And yes, much like everything else on a job site or at a manufacturing facility, choosing the right double sided tape for the specific application is paramount.

How is Double-Sided Tape Used?

Did you know that in auto manufacturing, double-sided tape has been replacing rivets and fasteners for years and is used to attach everything from dashboards to specialty car appliqués? Or that RV and truck manufacturers use specialized double-coated tape to bond panels together and fasten exterior mirror glass to the mirror housing bezel? Here are just a few other applications where double-sided tape plays a major role:

House Wrap and Vapor Barrier Seaming. Use double-sided tape to overlap house wrap seams so water does not migrate behind it. To reduce labor, use a high-performance double-sided tape to attach vapor barriers to walls in crawlspaces instead of using screws for a more air-tight seal. Learn more about this increasingly important process with our guide.

Acoustics and Sound. With more buildings becoming airtight, sound is becoming a big issue. Double-sided tape is often used in manufacturing to attach foam to wall panels or flooring underlayment to floors.

Graphic Arts & Signage. When it comes to bonding, double-coated tape is the go-to tool of choice for this industry. Choose from a variety of adhesion levels based on what you need to stick together.

Convention or Expo Events. Every exhibition hall that lays down temporary carpet uses a very special double-sided carpet tape which is removable after the trade show and leaves no residue. When securing and holding (think red carpet) carpets in place for major events or trade shows, it’s double-sided fabric tape to the rescue. These tapes typically feature a medium adhesion and tack, which allow for removal without residue.

Splicing and Tabbing. For paper mills and paper corrugators, double-sided tapes are paramount to virtually every core-starting, splicing, or tabbing requirement.

What is Acrylic Foam Tape and Why Is It So Popular?

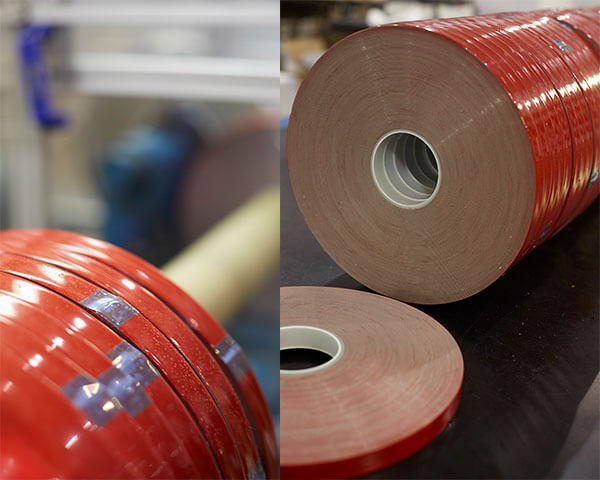

Acrylic Foam Tape (a.k.a. ECHOtape’s Ultra Bond Tape) is comprised of a layer of foam core that is coated with acrylic adhesive on each side, and covered by a red liner. It is stronger and will last longer, particularly in harsh conditions such as exposure to direct sunlight or extreme cold than most other tapes. Two key benefits of this adhesive tape are its strength and durability.

Indeed, acrylic foam tape has replaced screws, rivets, adhesives, and bolts in automotive, as well as other vehicles in transportation. Previously, manufacturers were forced to use metal fasteners, however, these had a number of drawbacks including the probability of rusting over time. As an alternative, this adhesive tape, which is water-tight/air-tight and rust-free, solves two problems with one solution.

The simplicity of the design is what makes acrylic foam tapes in general so easy to handle, but actually, each component — core, adhesive, liner — is carefully selected and engineered to perform under a range of conditions.

Foam Core: Foam is at the core of the functionality; it helps distribute the load. Available in a range of thicknesses and weights, it provides bonding between dissimilar, and uneven surfaces. Keep in mind: The holding strength of the bond is determined by the surface area available for taping.

Adhesive: Here, it’s the acrylic adhesive that delivers strength and durability, allowing it to meet more demanding holding requirements.

Liner: Release liners are specifically engineered to provide an easy release from the adhesion of the acrylic foam tape itself. Our red liner exists to maintain the integrity of the “stickiness” while keeping the adhesive layer protected from environmental elements during shipment, storage, and use.

While acrylic foam tapes can perform a variety of functions, it isn’t the only double-sided tape on the market. And it may not be the right tape for your job. Here’s how to find out:

4 Steps to Choosing the Right Double-Sided Tape

Speaking of double-sided tape, there are many different options available on the market. Before you just reach for the first one you see, ask yourself these 3 questions first:

Step 1: What are the two surfaces you are bonding?

Choosing the right double-sided tape begins by evaluating the surface characteristics of the two substrates you’re trying to stick together. For example, the flatter and smoother the surfaces are, i.e. glass, aluminum, PVC, the thinner the tape can be. Conversely, the rougher the surface is, i.e. wood, cement, brick, stucco, the thicker the rough surface adhesive tape needs to be to provide adequate contact.

Step 2: What is your surface energy?

All surfaces have a property known as surface energy, the degree of attraction or repulsion force of a material surface exerts on another material. Substrates with a high surface energy form very good surfaces for bonding, like glass, glazed tile, and bare metals. Plastics can vary from reasonably easy to very poor. For example, polypropylene and polyethylene are very hard to stick to and call for a higher adhesion and a very tacky adhesive.

Conversely, a material like silicone has such “low surface energy” that conventional adhesives won’t stick to it at all. Working with this material would, therefore, require an incredibly tacky and/or silicone adhesive.

It’s also important to take treated surfaces into consideration. For example, if a surface is coated with paint, the tape might stick well to the coating, but it there is a weak bond (low surface energy) underneath, the tape and the paint might peel off.

Step 3: What temperature resistance do you need?

Next, take your environment into consideration and choose a temperature-resistant tape. The tackiness of the adhesive tape is very temperature-dependent, and the colder the conditions, the poorer the bond will be. If you must work at lower temperatures, then use a double-sided tape specifically designed for colder climates. The same holds true for extremely hot or wet conditions.

Humidity, dirt, and UV conditions all play a role. Choosing the correct temperature-resistant tape for the climate variables at hand is very important!

Step 4: What other conditions should I consider?

When choosing the best double-faced tape for your project, it’s worth asking yourself these other key questions:

- How long do you need the tape to hold? Meaning, do you need a temporary or permanent solution?

- If you need to remove the tape, do you need it to be clean removal?

- What will the tape be exposed to while you are applying it, and afterward? Consider moisture, heat, cold, water, UV, and dirt.

- Does the tape need to be a certain thickness for the application to work?

- What width do you need?

- Is there any heat involved in the application process, i.e. in manufacturing?

- Are there any specifications you need or are required for the job at hand (i.e., EPA codes, UL approval, etc.)?

What it all boils down to is knowing these three things: your job, your materials, and your field conditions. Only then can you match the right adhesive with your project and decide if you need heat-resistant, extra wide, or specialty outdoor double-sided tape. By thinking about and answering these questions in regards to the adhesive, you can increase the longevity and success of your projects.

Take a look at ECHOtape’s double-sided tape solutions here. And if you still have questions about double-sided tapes and how to leverage them on your next job, please contact us: here at ECHOtape, we’ve made it our passion for more than 40 years to help professionals with their sticky issues!

Click here for our complete selection of insulation tapes.

Also, check out some of our most popular tapes:

Outdoor double sided tape

Thermal tape

FSK tape